We recently completed a project that was a good example of our engineering design department and mechanical installation team working together to provide a holistic service for a food sector manufacturer.

Our customer wanted to replace a product tank assembly and tasked Vogal Group with installing the new vessel along with the associated pipework installation. The purpose of the project was to save steam on beet cost and reduce the secondary downtime for cleaning the heaters. This has lowered the carbon footprint and significantly reduced the cost of sugar production.

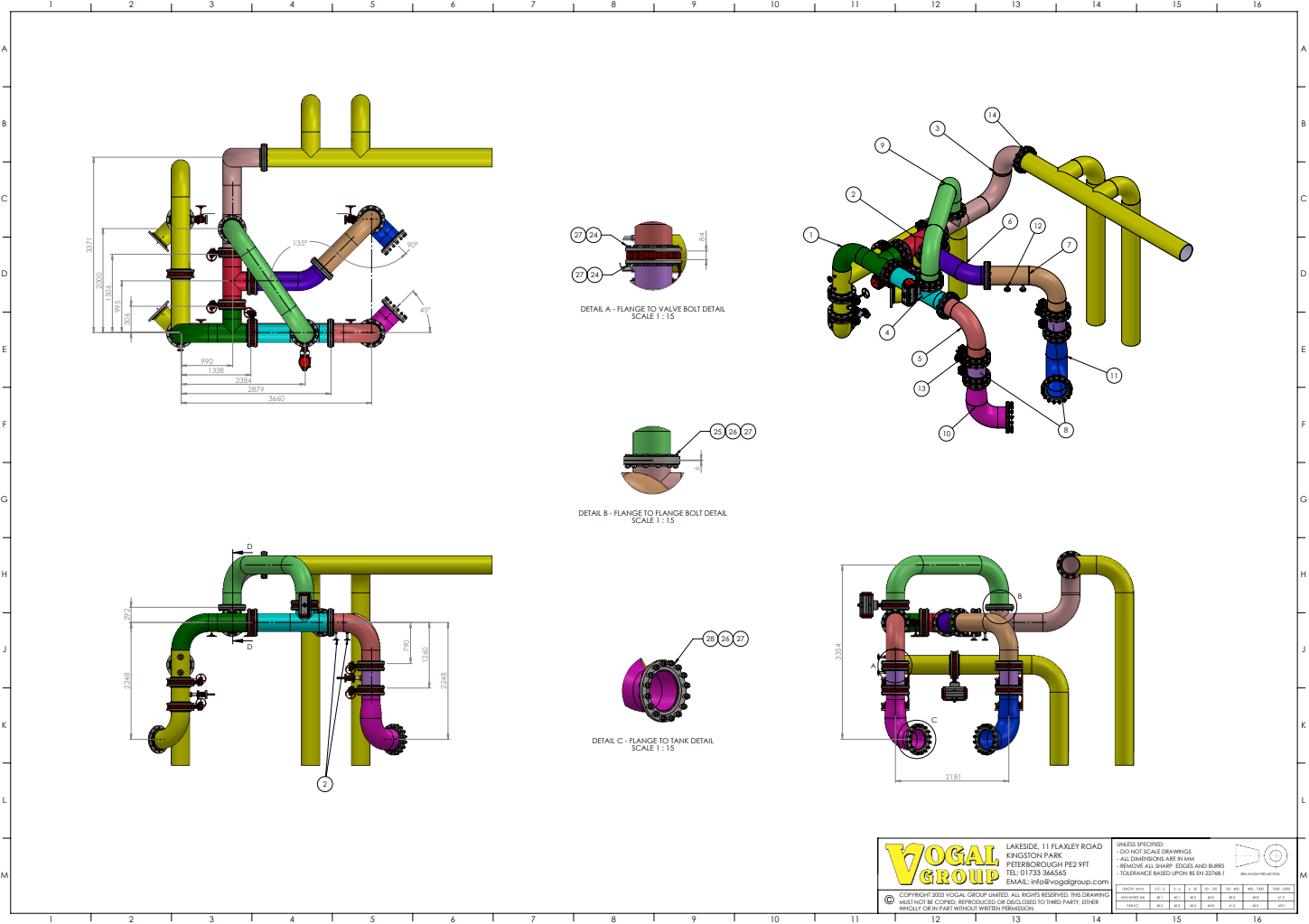

We designed the product inlet and outlet pipework with the inclusion of a bypass line (the non-yellow sections of pipework in the drawing). The yellow pipework was the existing pipework that was not changed but was connected to the new Vogal Group designed pipework. The pipework was modelled and drawn using SOLIDWORKS based on dimensions taken from site surveys and existing site drawings of the tank and the surrounding steel work.

If you need external mechanical installation support, please Contact us